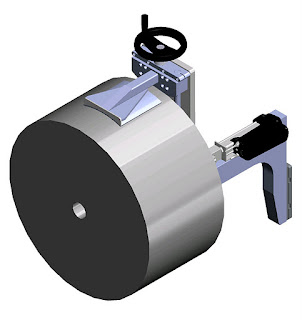

The stainless steel roll handling equipment from Packline Materials Handling is designed for loading and unloading rolls of film or packaging material where a longer distance reach is required. This is achieved by means of a counterbalance unit.

Packline’s latest design compliments the existing range of reel or roll handling equipment for the food, drinks and medical processing industries.

The roll handling equipment with counterbalance weight is suitable if the lifting attachment reach extends beyond the legs of the lifter, or if there is restricted leg access when lifting the rolls of material.

The counterbalance weight is added to the sides of the roll handling equipment.

The footprint of the lifting equipment is not increased with the addition of the counterbalance unit.

The standard lifter base width remains at the size of 500mm.

This roll handling application with counterbalance ensures that the most stable lifting solution is achieved.

The counterbalance weight is added to the side of the lifter and therefore in most cases the lifter’s footprint is not increased over the 500mm wide standard base.

Maximum lifting capacities up to 300kg are available.

The new reel or roll handling equipment is suitable for:

· Reaching beyond the legs of the roll lifting equipment.

· Situations where there is restricted lifter leg access when lifting and handling rolls or drums.

Bespoke attachments can be designed to provide a lifting and handling solution for most types of roll, reel, drum or barrel.

For further information on roll handling equipment with counterbalance or the full range of lifting and handling equipment, please contact Packline Materials Handling on +44 (0)1202 307700 or visit http://www.packline.co.uk