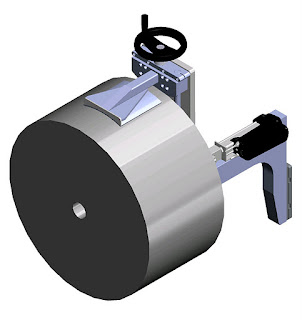

This new reel handling concept from Packline Materials Handling overcomes the difficulty of handling telescoping rolls or reels.

Telescoping reels can occur if the material is not wound tightly enough around the core of the reel. This can make the reels difficult to lift and handle via the core. This new and innovative way of clamping the external diameter of the reel of material, whilst still handling via the core, eliminates this problem.

The reel is rotated using a linear actuator whilst the clamping and finger expansion is carried out via hand wheels.

This is a quick and simple way to re-orientate difficult to handle reels of film or packaging material.

The clamping vertical spindle is built to order to suit specific requirements, handling a wide range of reel diameters and widths.

· Maximum Safe working load = 130kg

· Reel Diameters = 450-750mm

· Electrically operated linear actuator to rotate reel 12 or 24v

Packline Materials Handling has been designing and manufacturing materials handling equipment since 1993, and with its range of stainless steel roll and drum handling equipment has established itself as a leading supplier of materials handling equipment for the food, drinks, dairy, pharmaceutical and medical processing industries.

Packline are also suppliers of mild steel and stainless steel heavy duty lifting equipment with the option for fork legs or a range of attachments, for reels and drums to suit both warehouse and industrial needs.

In addition, Packline's vacuum lifting equipment solves a wide range of handling and lifting problems in all industries.

No comments:

Post a Comment